Process Engineering

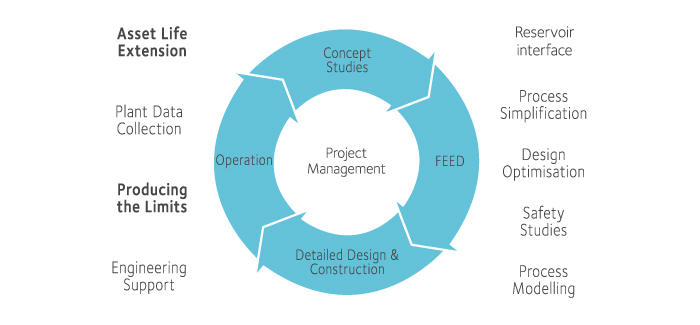

PEAK offers a fresh approach to engineering consultancy, with interactive methodologies and experience from a cutting edge oil and gas industry. Our services are meticulously developed to enable our clients to get the best from their assets, extending lifecycle and boosting production and profitability.

We work to produce and deliver a service tailored specifically for your company’s individual requirements. From concept and design, to delivery and installation, we take care of every aspect of the project lifecycle, helping you to achieve the best possible results.

Take a closer look at what our bespoke services have to offer.

Reservoir Interfacing

PEAK offers its clients the service of reservoir interfacing, which aims to model the boundary between the reservoir and topsides. This can be exceptionally beneficial, allowing for the optimisation of well flowrates, given the limitations in topsides equipment. It can also allow for the optimisation of topside operating conditions, and of the optimisation of design and operation of secondary recovery techniques.

Our engineers have previously utilised this service to maximum effect. For example, it has provided support to production operations by optimising choke positions, delivering maximum production under high water cut operations, with produced water handling constraints. It has also been used to determine optimum distribution of gas lift, to make sure maximum production rate was achieved. Finally, reservoir interfacing has allowed us to use the well performance curves to optimise enhanced production resulting from topsides depressurisation.

Process Simplification

Simplifying the process helps reduce the OPEX while increasing plant availability and reducing hydrocarbon leak sources. This results in reduced lift costs with increased safety.

Process Simplification has been the cornerstone of the growth of PEAK. We have provided the concept and supported the engineering behind an ongoing process simplification project. This has seen the processing plant reduce from eight to three separators, the flare reduce from a two to one system, the drains brought topsides, and the majority of the gas plant removed from service. This was all achieved with no reduction in production rate; only improved OPEX, availability, and reduced hydrocarbon risk.

Design Optimisation

Design Optimisation is possible through knowledge-based engineering and the use of appropriate design techniques. Here at PEAK, we have a skilled team with a breadth of industry knowledge in the associated technologies and techniques used. They operate a suite of design screening tools including CBA, value engineering, HAZOPs, HAZIDS, and cold eyes reviews, amongst others.

At Peak we have a wide range of experience in oil and gas field technologies and have utilised this, along with appropriate optimisation tools, to regularly add value to ongoing projects. We thrive on the challenge, and it is from this success that we gain repeat orders – the source of the majority of Peak’s business.

Process Modelling

Process Modelling is a key tool to understand the effects of process events in order to ensure the optimum design is delivered and/or the adequate level of protection provided. PEAK has used process modelling for such activities as debottlenecking, design assurance, safety instrumentation response times, fault-finding, and condition monitoring.

Recent examples of this service have seen the team produce a fully integrated dynamic model including well profile, pipeline hydraulics and topsides operation. This allowed the team to discover the best design and operating conditions of a jet pump (educator), which interfaced new and old wells, despite the fact that it was limited by the existing design constriction of a first generation facility.

This service has also enabled us to evaluate the dynamic pressure build-up in a flare system that had depressurised into a liquid filled pocket, within the flare pipework. This then allowed us to determine the resulting dynamic load and hence input to stress analysis.

Finally, process modelling has permitted us to undergo the development of a process control simulator. This allows operators to learn and discover the process plant prior to start-up.

Technical Safety

PEAK upholds the assessment of safety and risk factors as the first priority during any project in which we undertake.

Production facilities are complex and operate in unique environments with potential for health and safety issues or loss-making downtime. The ability to manage or mitigate undesirable events is probably the single most important factor in achieving business success within our sector.

Our technical safety and risk team can cover many of the activities associated with safety, risk and equipment reliability, from the preparation of individual studies through to the provision of a HAZOP chairman. To enhance our offering, PEAK Global has also developed a SIL verification tool to help clients quickly assess SIF loops using the latest Industry standards.

Our full service offering includes:

HAZOP and HAZID Reviews – Where teams are specifically chosen to match each project and ensure optimum results.

Risk Assessment, SIL and Reliability Studies – A range of high-end technical safety engineering is available from PEAK’s engineering network.

Layer of Protection Analysis

Active and Passive Fire Protection Design and Optimisation – PEAK is able to provide a full suite of technical safety engineering capability through association with loss prevention specialists.

API Recommended Practice

Blowdown and Flare Studies

SIL Verification Tools – Bespoke in-house SIF loop verification software and service.

QRA

ALARP Assessment / Demonstrations

Design & Operational Safety Reviews

Safety Studies (Fire & Explosion, Gas Dispersion, EERA, ESSA etc)

Design & Operations Safety Case

Safety Management – HSE Plan, Safety Philosophies, HSE Audits/Reviews.

Asset Life Extension (ALE)

For the majority of older oil and gas facilities, the production and processing environment has changed significantly since its early days. Typically, the current produced water flow rate is similar to the original oil production rate. Additionally, increasing operational and maintenance overheads and obsolete control technology, often threaten to bring lift costs above production revenues.

To overcome this challenge, and to create an additional 10-15 years of asset production, PEAK recommends that operators create a simplified, safer process in a controlled environment, whilst balancing the requirements of a capital budget, against reduced OPEX and process risk.

PEAK is proud to have developed groundbreaking ALE techniques and methodologies to bring our customers an extended, safe and profitable asset lifespan. We undertake everything from reservoir development, drilling programmes, and updating facilities, to receiving new production profiles, ensuring asset integrity, and implementing operating strategies. This has gifted us with considerable experience in creating unique environments for our clients, and a strong portfolio of life extension projects. From concept to delivery on minimum downtime, and with a comprehensive HSE delivery, PEAK strives to provide an all-encompassed service that provides the best possible tangible benefits.

Here’s an example of our ALE work for EnQuest in action.

The benefits of ALE are considerable. The figures below are based on the work with one of our clients:

- 15 years additional oil production

- $3.8bn additional oil revenues

- 50% additional oil production

- 30% risk reduction

Production Efficiency (PTL)

PEAK is proud to deliver a unique service, which aims to rapidly maximise revenues gained from your assets. From reservoir to export, PEAK provides an all-encompassed service called Producing the Limits (PTL)© – a methodology that identifies where additional production can be gained in the short-term, typically focussing on a period of 1-2 years.

Our multi-disciplined team creates an optimised model of your production facility from concept to delivery. This incorporates several steps – from defining system boundaries and data acquisition, to the basis of design, model development and cost benefit analysis, through to field development, and reporting. This approach is highly successful, with the total production facility model incorporating specialist knowledge on each individual engineering discipline into a clear cost benefit analysis. This, in turn, maximises the limits of the entire production chain.

The maximised limit of the facility is not just a theoretical potential, but also an engineered practical, cost-effective solution.

Typical Producing the Limits benefits:

- 20% Additional Production

- 15% increased production availability

- 10% reduced OPEX

- 90% of Platforms could benefit

Opex Reduction

Reducing operational (OPEX) costs is a key driver for many companies, no matter what sector. At PEAK, we integrate key elements from the oil and gas industry in order to achieve the most cost effective results, whilst maintaining optimum asset performance.

These key elements are:

Power + Chemicals + People + Technical + Safety + Health and Environment + Maintenance

These empower us to identify the assets that should be focussed on, and how to achieve:

- Production optimisation with Producing the Limits (PTL) © – identifying the potentials and safe limits of your asset

- Asset Life Extension (ALE) and process simplification

- Process safety/loss prevention

- Debottlenecking

Here at PEAK, we offer a combination of traditional engineering techniques, coupled with pioneering, intelligent process engineering, and technical safety to achieve the best possible results.